A team of Thomas Jefferson University medical students had an idea about how to help hospital patients get better, more restful sleep. They came to NextFab’s Product Development team in need of professional design and engineering expertise to make this idea a reality. We partnered with these innovators to overcome their funding and product design challenges and put them in a position to test their concept in the real world.

Circalux was a startup company founded by three Thomas Jefferson University medical students who noticed how disruptive hospital lighting can be to patient sleep during their medical school training. They aimed to address this problem by developing lighting products that combat the most disruptive stimulus to our circadian rhythm – light pollution at night. The product they came up with was the Circalight, a smarter night light that responds to the presence of caregivers by automatically illuminating with soft, warm light specifically sourced to minimize disruption on sleep physiology. One of the novel features of the Circalight is that the light brightens as a caregiver approaches and dims as they recede, thereby providing a hands-free, minimally disruptive work area lighting.

Prior to coming to NextFab, the Circalux team had laid a solid foundation on which to develop the product. They had identified the problem that the product was intended to solve, researched the market landscape, identified their proposed solution, and protected their intellectual property by filing for a provisional patent. They also developed an initial working prototype and had a product design concept that they were interested in pursuing.

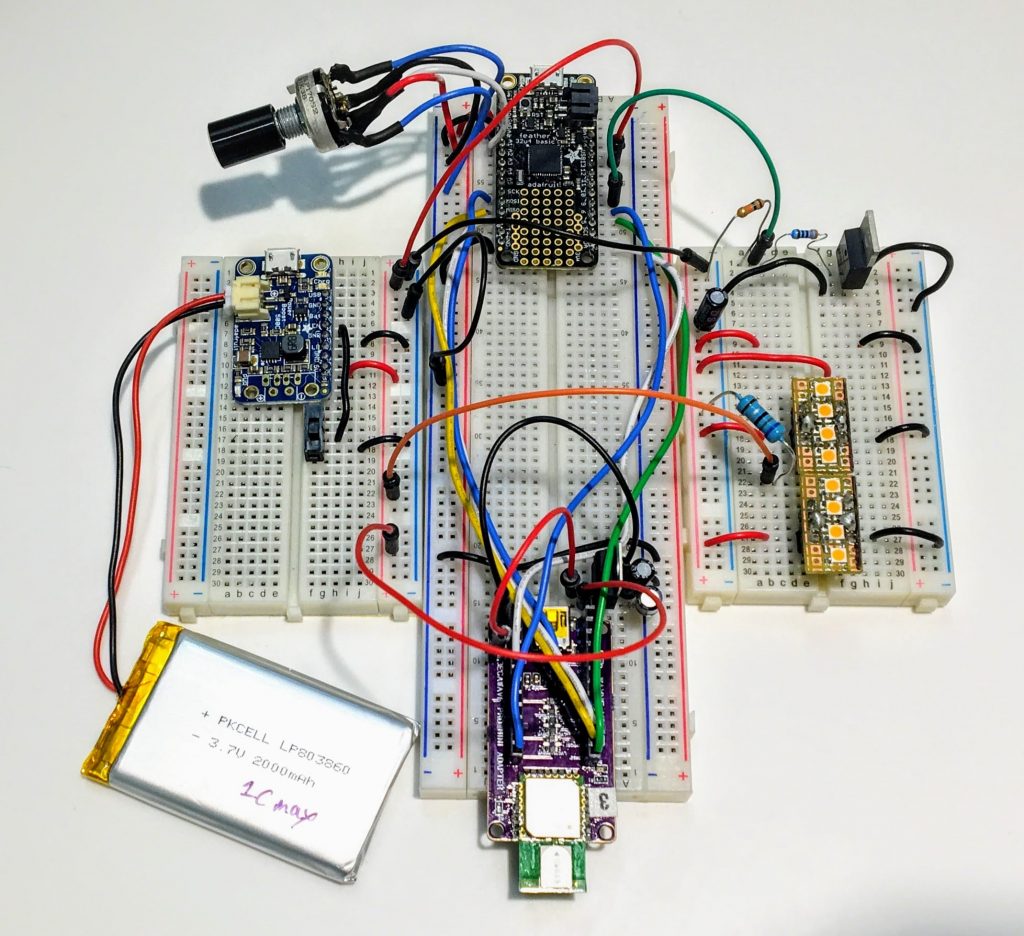

Initial prototype & design developed by the Circalux team prior to engaging our team

The Funding Question

While the team was in a great position to move forward, they knew that raising funding would be as big a challenge as developing the product. Bringing any product to market requires a significant investment. That’s especially true for a hardware product due to the large up-front cost of tooling and manufacturing in addition to the cost to design and engineer the product. Often hardware startup companies look to raise funding for product development from external investors, but Circalux was too early-stage for this. They needed a funding solution to fill the gap and enable them to take the next few critical steps in developing their product and business. Enter the Ben Franklin Technology Partners (BFTP) FabNet grant program and NextFab’s RAPID Hardware Accelerator.

The FabNet program aims to reduce the time and expense of prototype development through access to specialized facilities, equipment, and expertise required for design, simulation, and fabrication of products. As part of the program, BFTP provides up to $5,000 in non-dilutive funding to work with any of the FabNet partner organizations. NextFab is proud to be one of these organizations.

Circalux was able to partner with NextFab’s Product Development team to take advantage of these programs to turn their $5,000 initial investment into over $30,000 to apply to their product development efforts.

Our Approach

At this stage in the product development journey we advise our clients to take a step back and think about the biggest risks to product success. We like to frame the risks as questions that must be answered. We’ve found that systematically considering a wide range of risk categories provides a comprehensive picture of the areas that need to be addressed during development.

Those unanswered questions should be prioritized and only the highest priority ones addressed. Prototyping and testing is often (but not always) an effective way of answering those questions. Note: if you’re building a prototype that isn’t targeting a high priority unanswered question about the product or business, then you probably shouldn’t be building a prototype.

In this case, we worked with the Circalux team to hone in on these key questions:

+ Can we find a technological solution that enables the light to respond to caregiver proximity with adequate sensitivity and smoothness to deliver a delightful user experience? [Engineering Feasibility]

+ Will the lighting system integrate into caregiver workflows in the hospital environment? [Usability]

+ Will the product make the caregiver’s job appreciably easier? [Efficacy]

+ Will the product result in better patient satisfaction? [Efficacy]

We determined that the first question was the highest priority, as the primary product functionality hinged upon seamless proximity detection. To answer that question, we planned an initial project to design, build, and test a works-like prototype to demonstrate the proximity detection solution.

Proving out the Core Technology

The initial working prototype that Circalux had developed utilized single-point Bluetooth technology for proximity detection, where the light would detect a user based on the bluetooth signal from their smartphone. There were several pros and one major con to this solution. On the positive side, Bluetooth is a common and well-understood technology and is included in every smartphone. Unfortunately the initial prototype didn’t offer enough resolution and sensitivity for this use case, which required distance detection resolution of less than 0.3 meters. We needed a better technology solution.

We first explored whether it would be possible to utilize Bluetooth in a way that offered improved resolution (e.g. by clever firmware implementation or a multi-point solution). Research showed that the best resolution we could hope to achieve was 1 – 3 meters, which wouldn’t work. WiFi was also eliminated, as it’s resolution was even worse. The answer came in the form of ultra-wideband Radio (UWB), which offers 10 – 30 centimeter positional accuracy and low power usage. Coincidentally, Apple included UWB technology in the iPhone 11 and is rumored to be coming out with their first UWB tags in 2020. Despite this, until the technology is more widely adopted, the product will involve a two-piece set: the light, known as the anchor in UWB nomenclature, and tag, which would be carried by the caregiver.

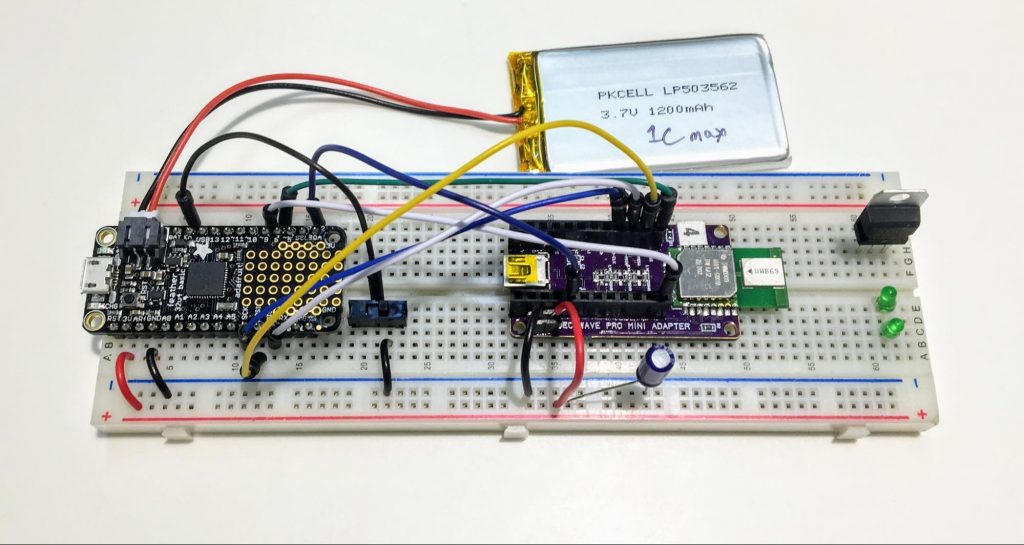

With the proposed technological solution selected, we moved onto breadboard prototyping.

During this step we were fully focused on proving out the core functionality of the device – control of the lighting based on proximity. The proximity detection itself was implemented first, which we were able to get up and running quickly. The bigger challenge came with implementing an algorithm to relate the light brightness to proximity in a way that felt natural to a user. This task was misleadingly complex due to the non-linear relationship between current delivered to the lights (which was being controlled by the proximity of the tag to the light) and perceived brightness by the human eye. The ramp up from what we perceive as “dim” to “bright” happens over a small current range and the changes in brightness before and after that range were mostly visually imperceptible. After extensive testing with the Circalux team, who were themselves target users of the product, the end result was a light that gradually and naturally went from dim to bright as the user approached the light.

Everyone involved felt that the primary question was answered affirmatively. The UWB solution did enable the light to respond to caregiver proximity with adequate sensitivity and smoothness to deliver a delightful user experience.

Creating the Beta Prototype

With the primary question now answered, we turned our attention to the next highest priority questions:

✔ Can we find a technological solution that enables the light to respond to caregiver proximity with adequate sensitivity and smoothness to deliver a delightful user experience? [Engineering Feasibility]

+ Will the lighting system integrate into caregiver workflows in the hospital environment? [Usability]

+ Will the product make the caregiver’s job appreciably easier? [Efficacy]

+ Will the product result in better patient satisfaction? [Efficacy]

Answering these questions involved getting Circalights into the use environment – the hospital. The Circalux team worked with Thomas Jefferson University Hospital to plan out a pilot study where 10 of the lights would be deployed in patient rooms. To support that study, we needed prototypes that merged the function of the works-like prototype with the form and aesthetics of the final product design. It also needed to be reliable, safe, and usable enough for people to use without direct supervision and with minimal instructions. In other words we needed to design and build a set of Beta Prototypes.

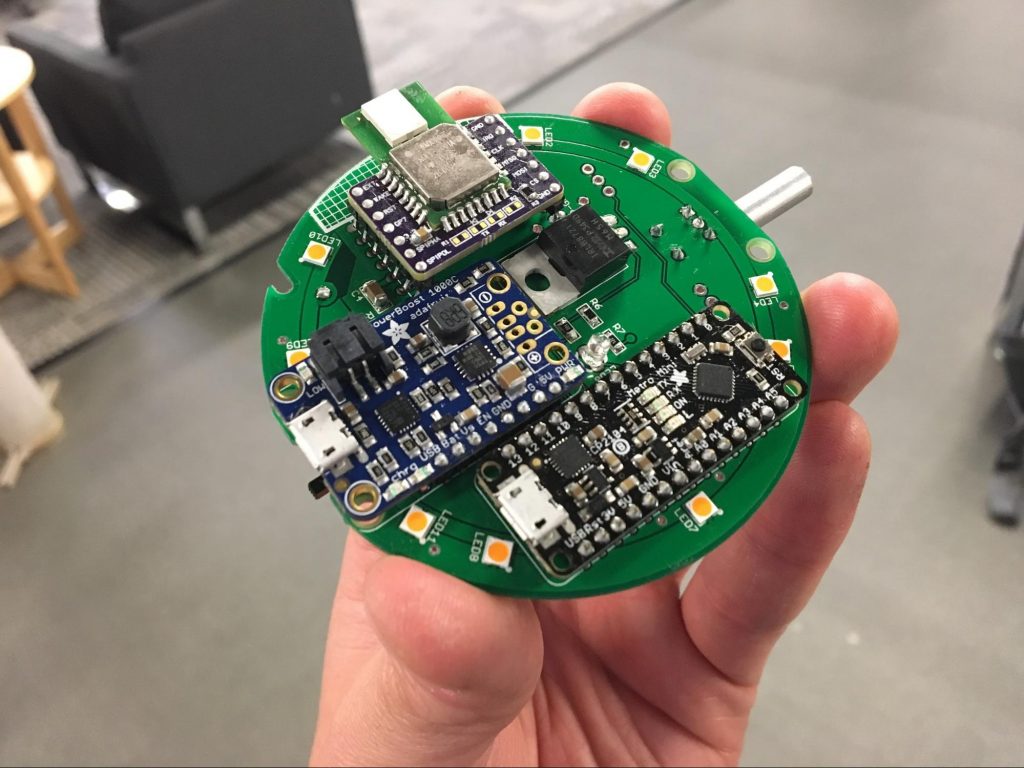

The Beta Prototype development involved moving the electronics from the fragile breadboard setup onto a more robust platform integrated into a durable, functional enclosure designed to align with the client’s vision for the end product.

Rather than spending the time to create a full custom printed circuit board (PCB) for the electronics, we opted to design an interconnect PCB. An interconnect PCB utilizes the components from the works-like prototype, but integrates the external wires within the layers of the PCB, making it more compact and durable while having the same functionality. This is a great interim step that gets you much of the benefit of a fully custom PCB in a fraction of the time.

A lot of thought goes into the design of an interconnect PCB. NextFab’s design team carefully considered functionality, aesthetics, usability, and how the prototype would be assembled. For example, it was critical for proximity detection functionality that the UWB chip was kept away from certain components to ensure a clean signal. It was also important that the internal LEDs were unobstructed to eliminate shadows when the light was activated.

The enclosure design was addressed in parallel with the electronics. We wanted to stay true to the original concept, which was both aesthetically pleasing and functional. The top hook-like design gives users the option of hanging the Circalight wherever they need it (such as over a door knob). The bottom gives the light a sturdy base when sitting on a tabletop or other flat surface. Our mechanical and electrical designers worked closely together to preserve these elements while updating interfaces for the new electronics and implementing changes to improve durability, usability, and assembly.

After iterating the design and ensuring the interfaces with the internal components were dialed in, the enclosure top and base were 3D printed in ABS plastic and nylon respectively. The top was sanded and painted to create a polished look that approximated an injection molded finish. The base material was selected for its strength and ability to effectively diffuse the interior light.

An enclosure was also needed for the tag that would be carried by the caregiver and enable the proximity detection functionality. Our primary concerns for the tag enclosure were durability and utility with less of an emphasis on aesthetics. That being the case, we opted for a commercially-available enclosure to save the time and expense of designing and fabricating a custom enclosure.

Pilot Study

With the Beta Prototype designed, built, and tested, the Circalux team was ready to go into the hospital pilot study

As expected, the testing resulted in a treasure trove of valuable feedback from actual users. On the positive side, caregivers reported that the light was bright enough to allow them to complete the required care tasks while still being very pleasant. Patients reported improved sleep compared to the status quo. Overall, the device was rated 8.8/10 for helpfulness on average. On the constructive feedback side, caregivers wanted longer battery life and improved aesthetics and usability from the tag.

The members of the Circalux team accepted medical residencies in different cities and decided to close down the company, but they learnt a great deal about operating a startup and developing physical devices that solve customers’ problems. We’ve been fortunate to work with them on this project and wish them all the best in their medical careers.

If you’re looking for a partner who can help you overcome the product development and funding challenges you face in bringing your innovation to market, we’d love to talk. Start the conversation by completing this form: